Protect Schedule and Handover

Our Solution: Valves to DIN/EN/ISO; 100% hydro/air tested at 1.5× working pressure. Complete documentation per lot. Capacity ≈150,000 units/year; emergency production can start within 72 hours.

Our precision-engineered valves ensure optimal performance across critical industrial sectors, meeting the most demanding operational requirements.

Extreme condition valves for upstream, midstream, and downstream operations. API-certified solutions withstanding pressures up to 10,000 PSI and temperatures from -46C to 538C.

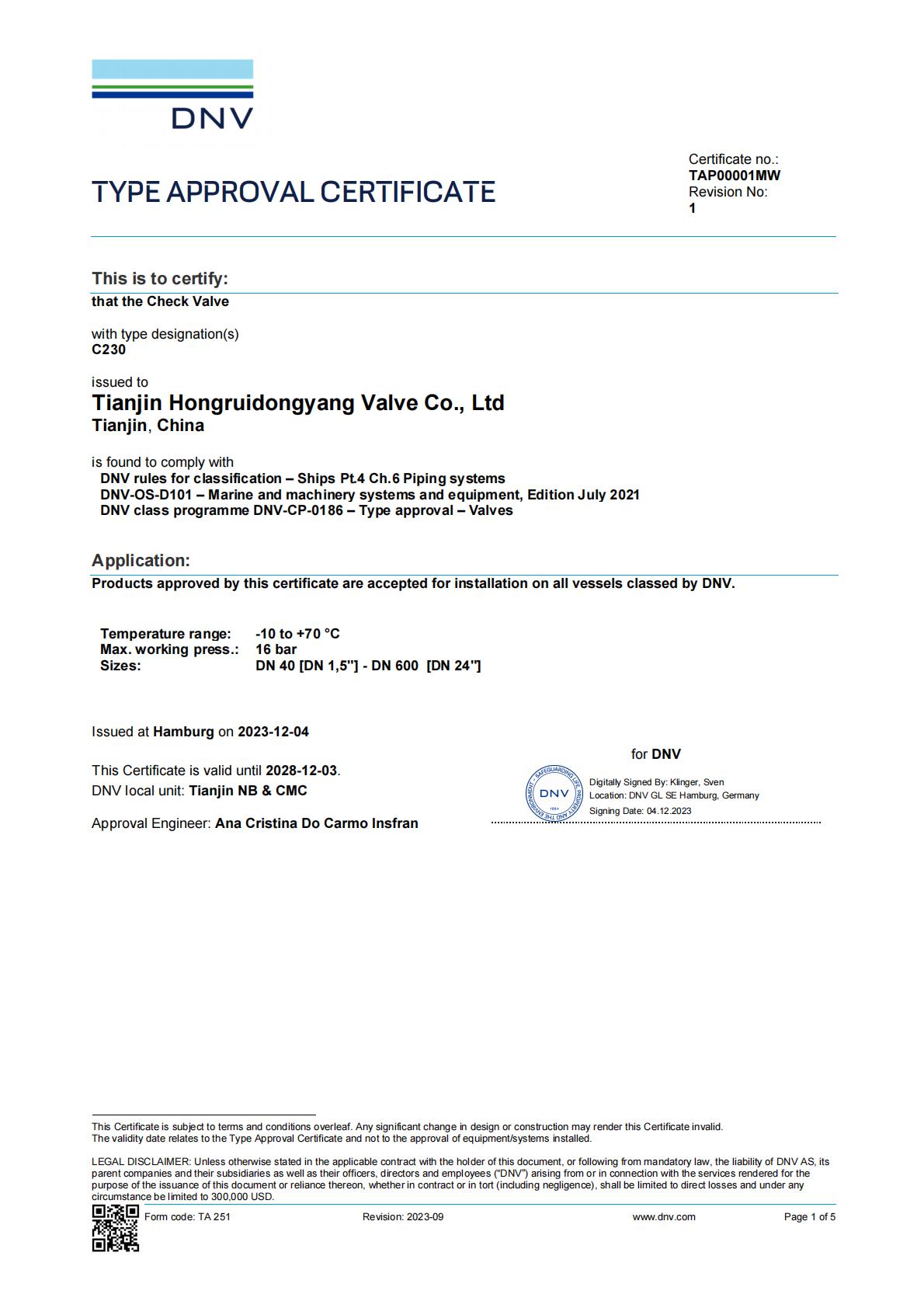

Nuclear-grade and thermal power plant valves. DNV GL certified for critical safety systems with 99.9% reliability rating and 25-year operational life expectancy.

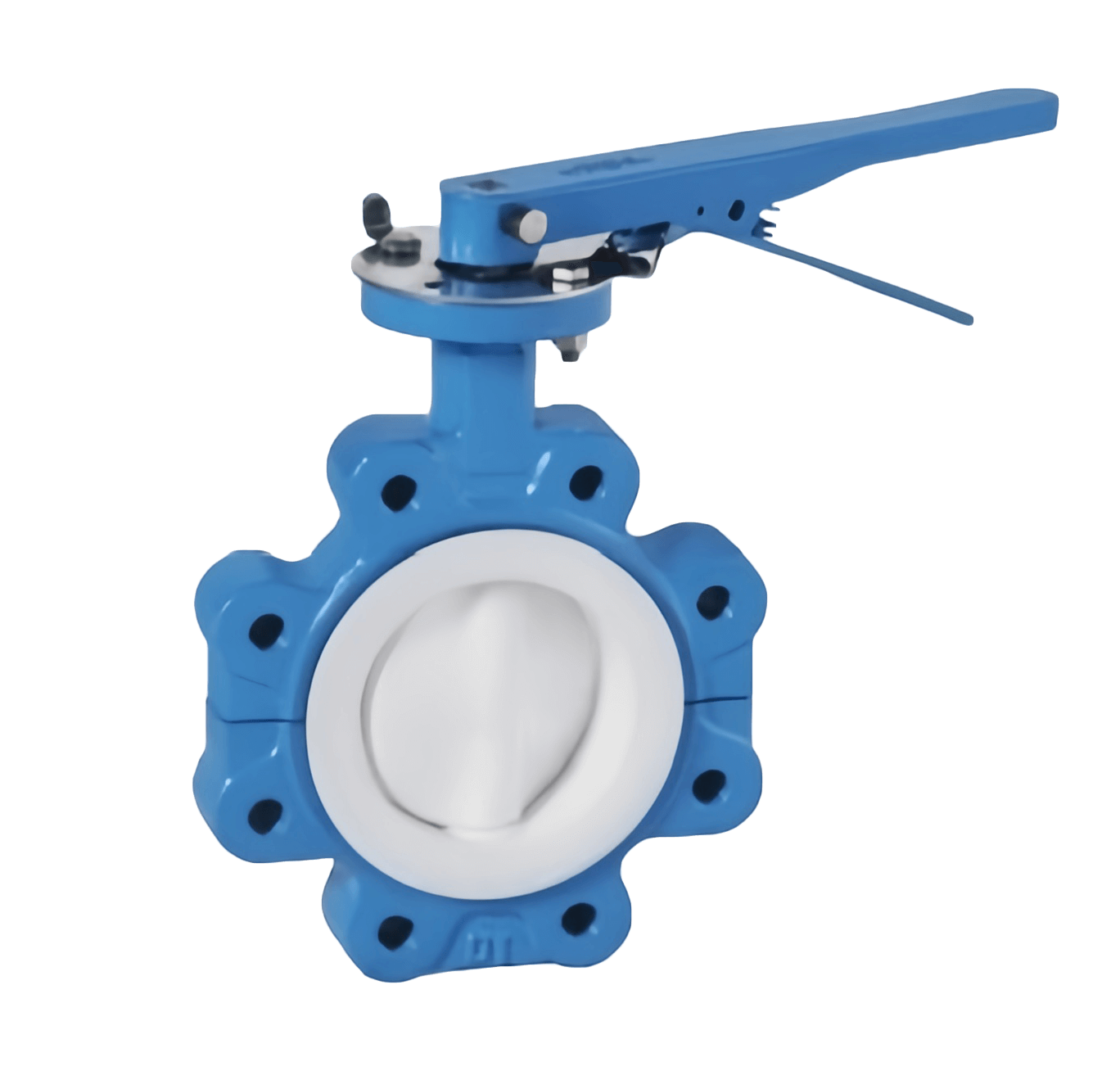

Corrosion-resistant valves for aggressive media handling. PTFE-lined and exotic alloy options with zero-leakage performance for hazardous chemical processes.

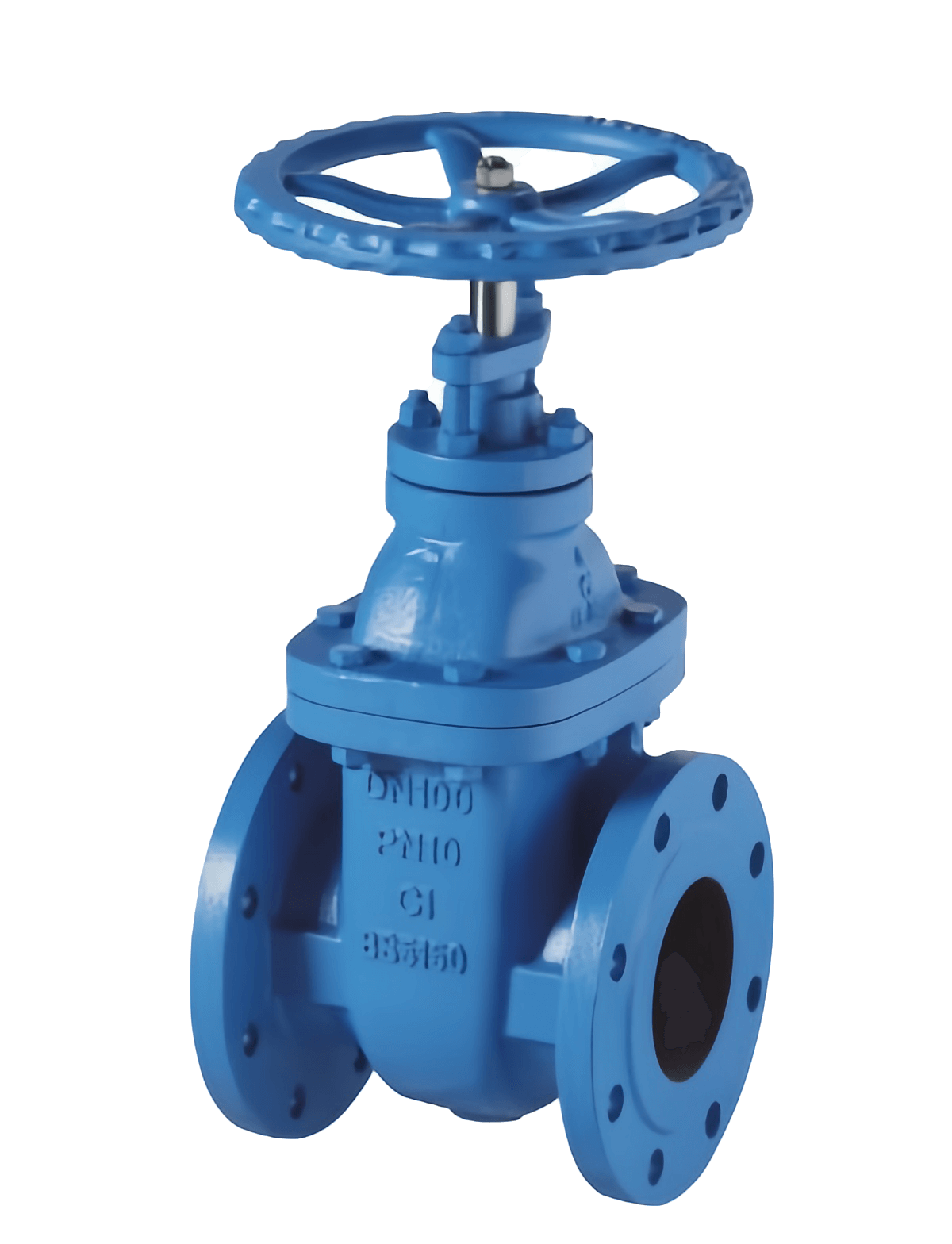

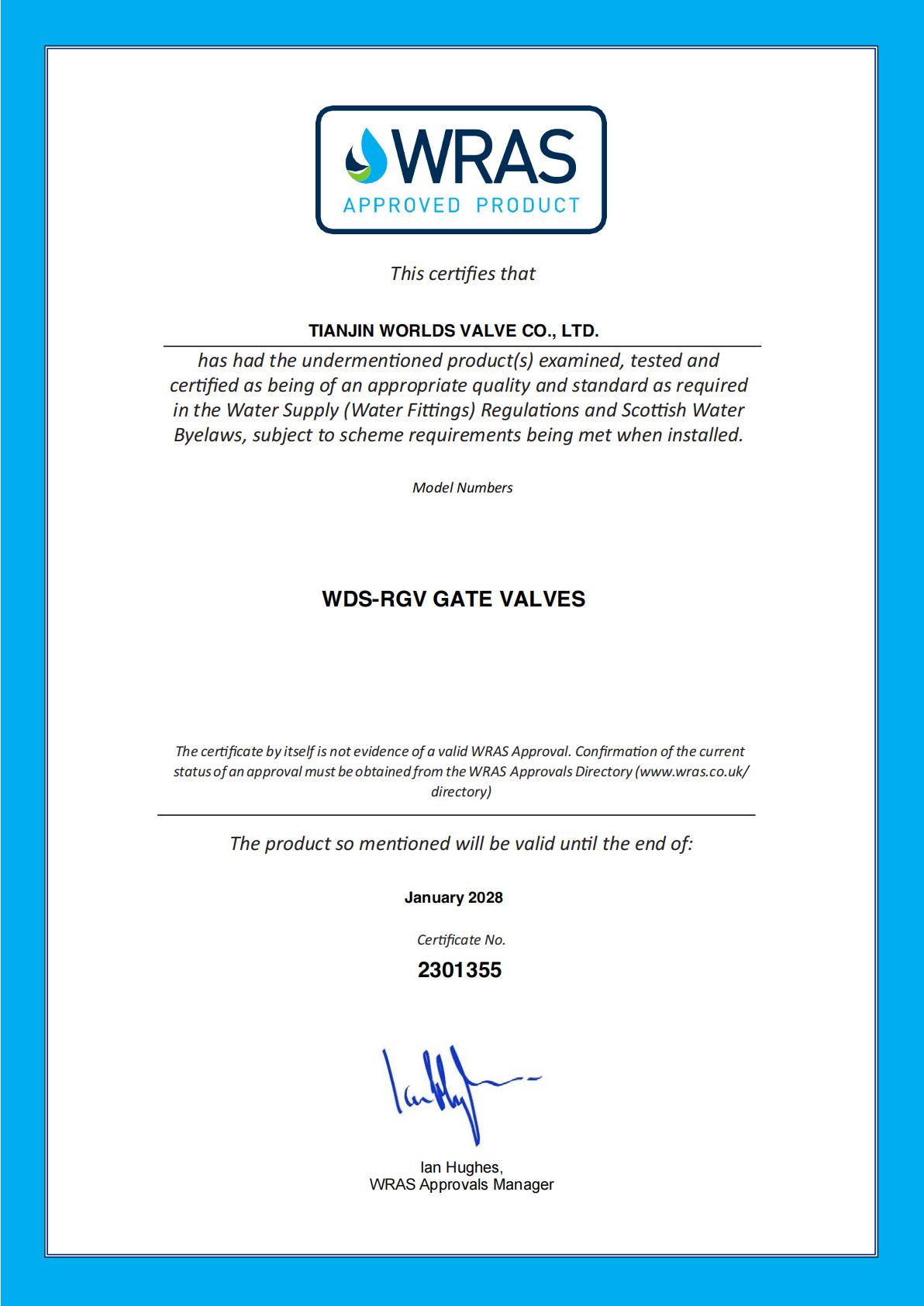

WRAS-approved potable water valves and wastewater treatment solutions. NSF/ANSI 61 certified with extended service life reducing maintenance costs by 40%.

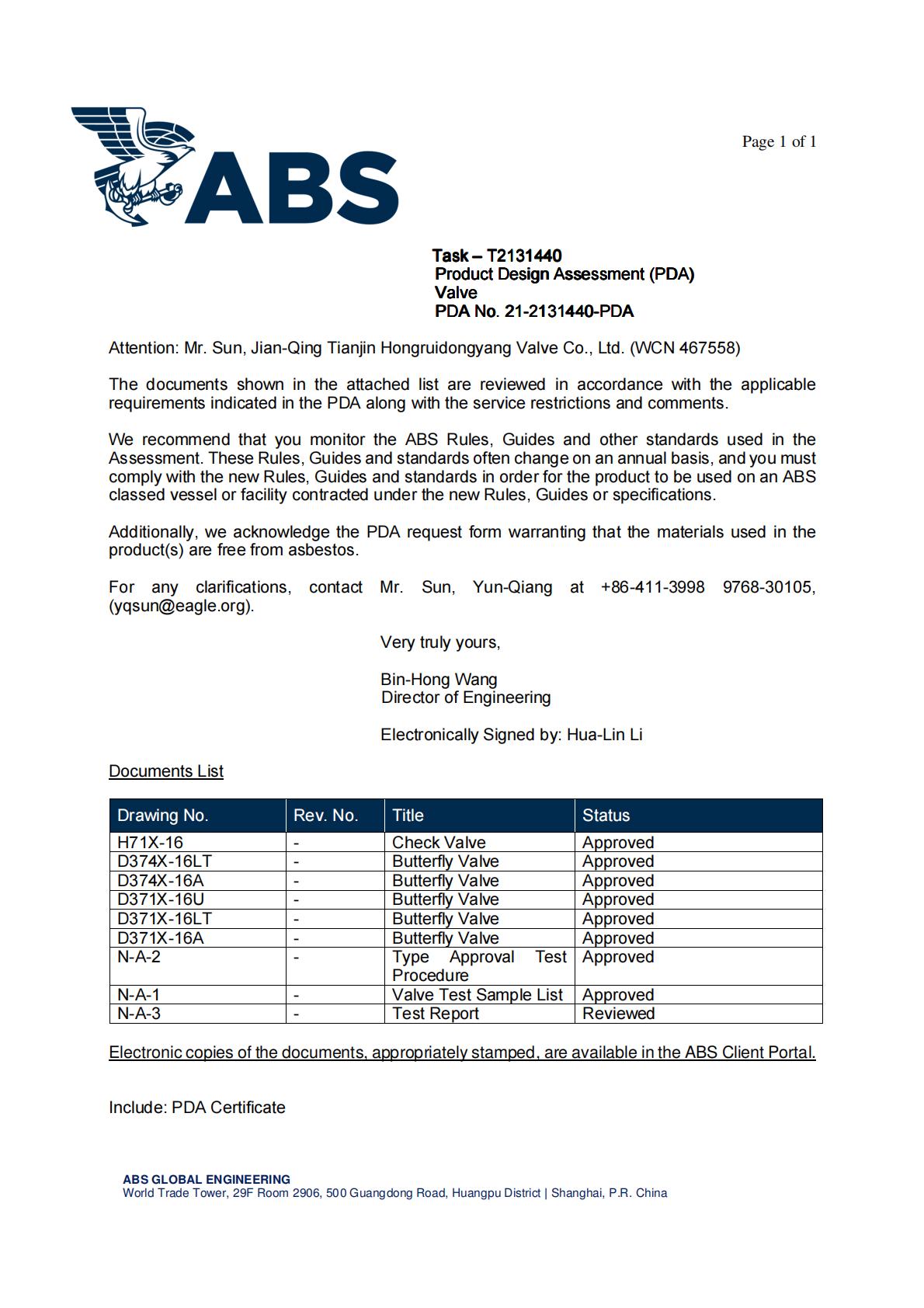

Marine-grade valves for harsh saltwater environments. DNV certified with superior corrosion resistance for offshore platforms and shipbuilding applications.

Heavy-duty valves for abrasive slurry handling and mineral processing. Engineered for extreme wear resistance and extended operational life in harsh mining environments.

Export-focused Chinese valve manufacturer: traceable QA, standard documentation and predictable delivery to address schedule, compliance and interface risks for EPCs and OEMs.

Each valve is designed and manufactured to exceed international standards, delivering exceptional performance across demanding industrial applications.

Evidence-based deliveries from a China-based valve manufacturer — built to ISO/CE/DNV standards with full traceable documentation for EPC, OEM and utility projects.

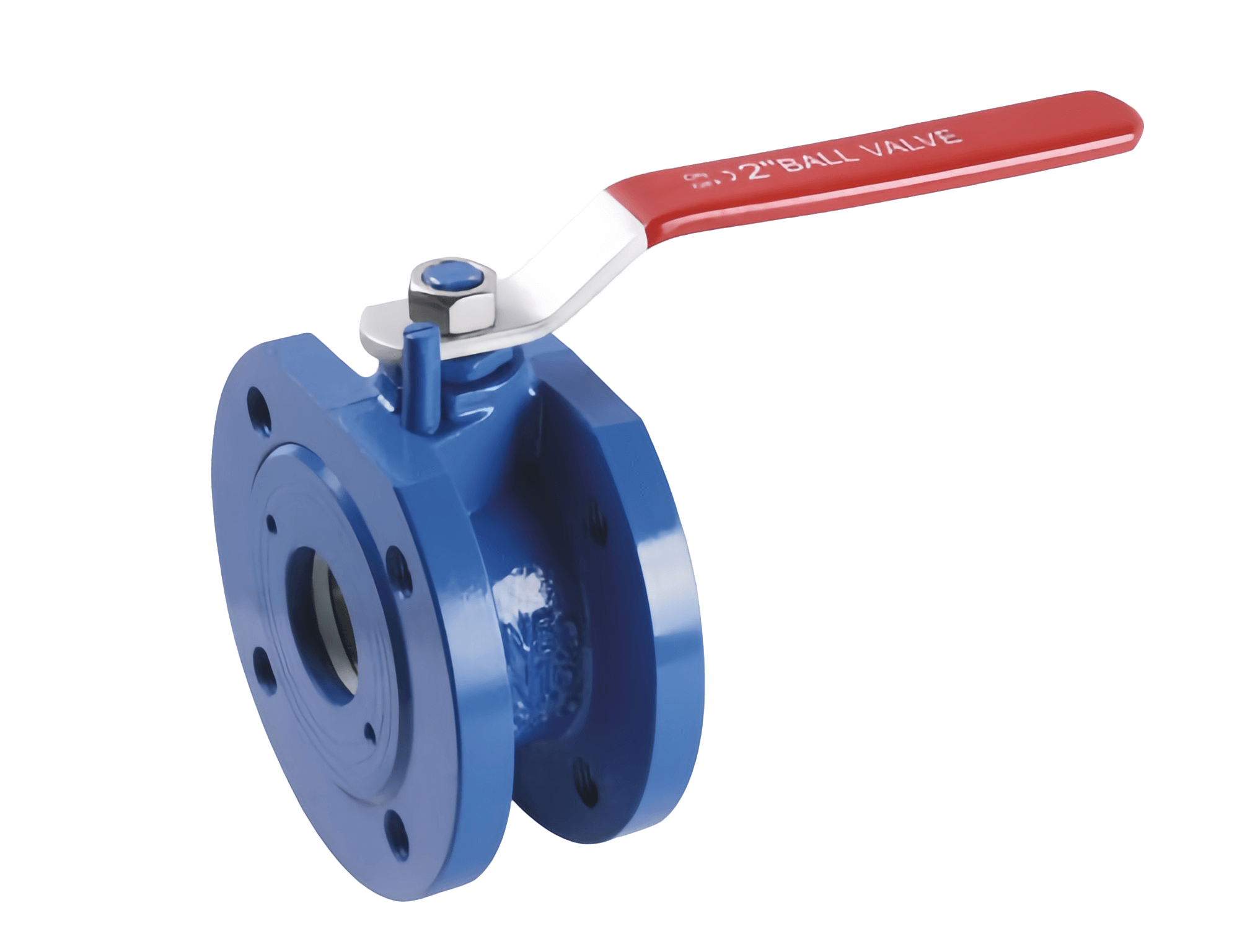

API/EN-compliant ball valves (DN50–DN300) engineered for 180 °C service. 100% hydrostatic and seat tests at 1.5× working pressure with full MTC/PMI traceability; staged shipments aligned to EPC schedule.

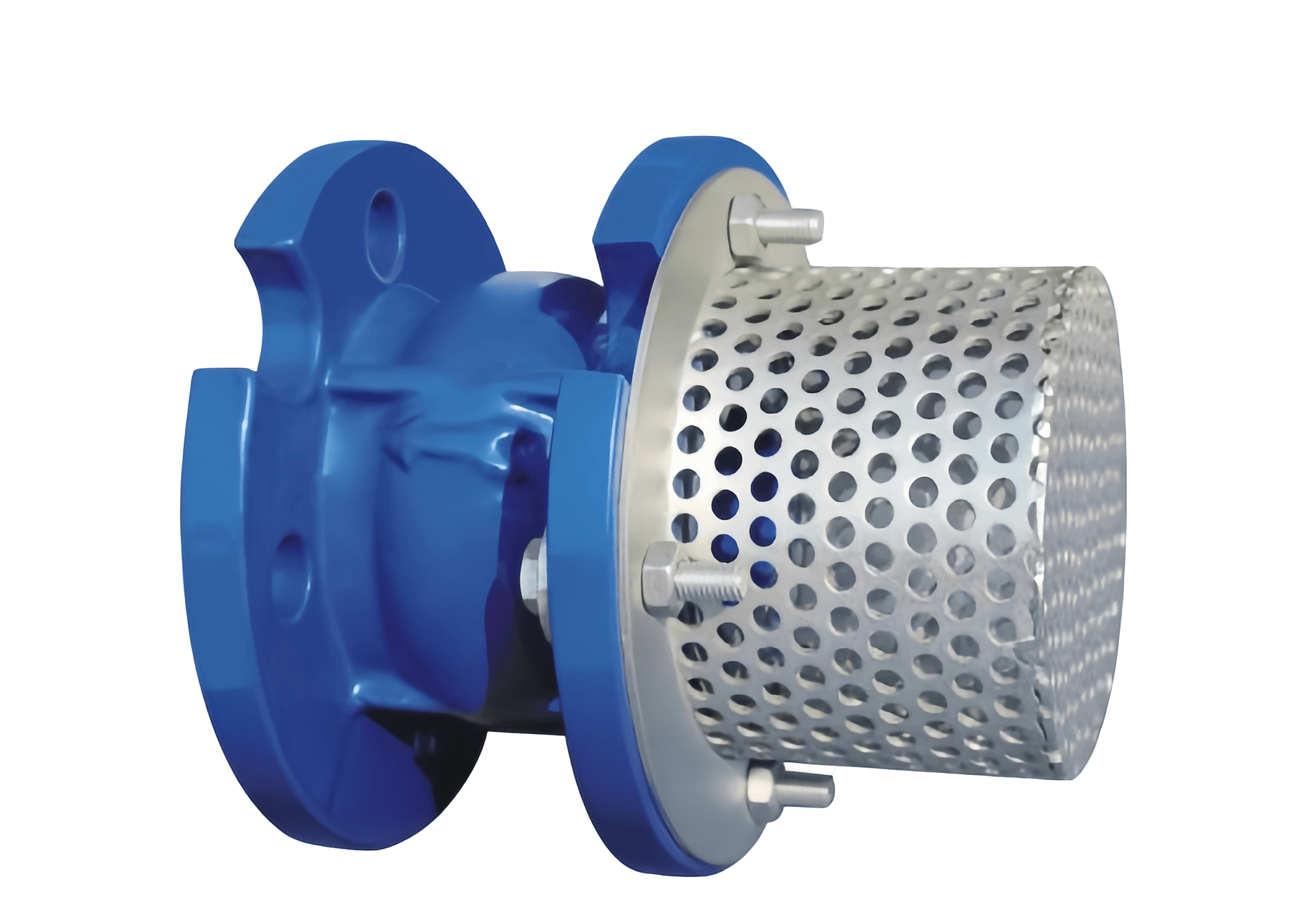

Re-engineered screen geometry to reduce line pressure drop by ≈25–30% versus legacy units under equal flow conditions; delivered with bilingual O&M manuals, material certificates and test reports.

Batch delivery of 200 elastomer-seated valves for high-cycle service. 100% seat/leak tests and batch traceability supported rapid approval; recorded defect rate <0.5% across the lot.

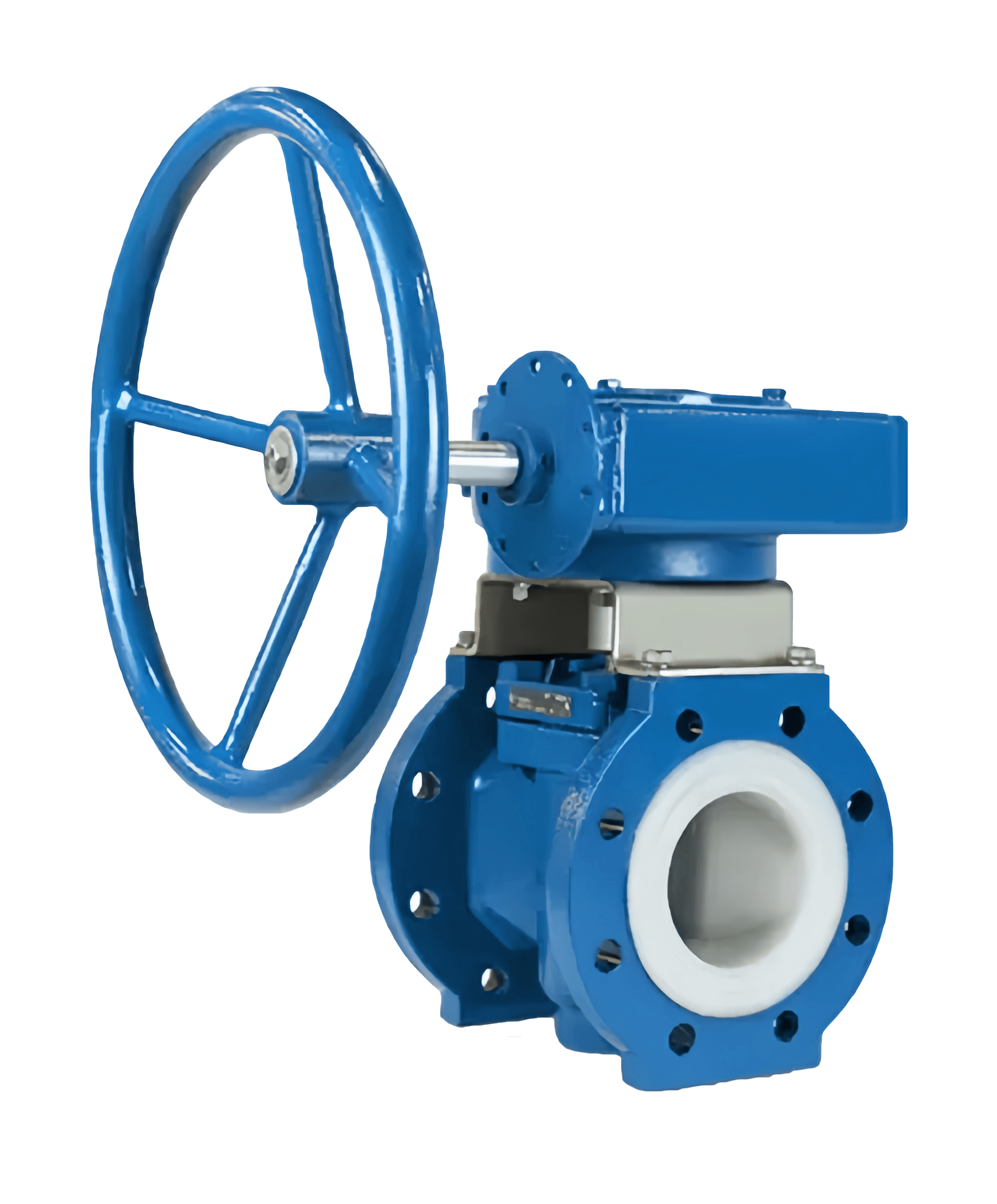

When standard valves are not a fit, our engineering team manufactures to your drawings and specifications—within DN25–DN3000 and PN10–PN25—with controlled lead times and full documentation.

Custom butterfly, gate, check, ball and other valves to DIN/EN/ISO, with repeatable machining accuracy and consistent performance across batches.

Cast iron, ductile iron, carbon steel, SS304/316L, bronze—supported by ISO 9001 quality control and CE/WRAS/DNV documentation when required.

Built to your CAD and specs; 3D modeling/FEA available; hydro/pneumatic tests at 1.5× working pressure with traceable records and full technical files.

24-hour initial response

Technical requirements review

48-hour detailed proposal

3D modeling & FEA analysis

15–25 day production

100% inspection & testing

Global logistics support

Full documentation package

ISO 9001–certified manufacturing in China integrating CNC machining, standardized assembly, automated coating, and hydro/pneumatic testing at 1.5× working pressure—delivering documentation-ready valves designed to ASME/DIN/EN/API norms for EPCs, system integrators and OEMs.

Process-controlled CNC machining with batch-level material certificates. Critical dimensions are 100% checked to drawings and recorded to ensure fit, sealing, and interchangeability across orders.

Dedicated assembly cells with calibrated torque control. Each valve undergoes hydro-test at 1.5× working pressure (air test on request); bilingual QA dossiers are issued per batch.

Automatic coating with controlled curing and pre-packing cleanliness checks. Export-grade packaging is optimized for sea freight with labeling to order specifications.

Built by an ISO 9001–certified manufacturer, our service framework focuses on cross-time-zone response, traceable quality control, and controllable lead times—from engineering clarification to factory acceptance and shipment.

Remote support in English for RFQs, drawings and application checks. Initial reply within 24 hours; corrective action or technical clarification within 48 hours for production or QA issues. Meetings via email/video are recorded and traceable.

Full-process QC under ISO 9001. Each valve is pressure-tested at 1.5× working pressure and serialized for batch traceability. Standard 12-month warranty; remedies (replacement/credit) are executed per contract after documented root-cause review. SGS/BV/TÜV inspection supported.

Schedule-driven planning with weekly status updates. Urgent orders can start within 72 hours; common DN50–DN300 models kept in stock. Typical lead time for customized items: 15–25 days. FOB/CIF/DDP terms and staged shipments available to fit project milestones.

Complete bilingual documentation: GA drawings, MTCs, pressure-test reports, IOM manuals and packing lists. CE/WRAS/DNV documents provided when applicable to the product scope. Remote product briefings and operation training can be arranged on request.

Our global customer base spans 11 countries across Europe, Asia, and North America, representing the world's most demanding industrial applications.

Senior Process Engineer, Singapore

"In petrochemical projects, equipment failures are simply not an option. After 18 months of continuous use, the valves have performed without a single issue. What I value most is the structured way they handled the project—from clear technical drawings to full test reports. As a buyer, that level of documentation and predictability makes me confident I can integrate their products into large-scale operations without risk."

Plant Manager, Germany

"Managing a chemical plant means every delay translates into real financial impact. The valves we sourced maintained full reliability under highly corrosive conditions, and all certifications were delivered on time and ready for audits. What impressed me was their quality management system—it wasn't about one good shipment, but a consistent process. That gave me the assurance I could rely on them for long-term procurement."

Chief Engineer, United Kingdom

"Offshore conditions are brutal on equipment—saltwater, pressure, and long pre-commissioning cycles. After two years submerged, the valves were still performing exactly as specified. But what made the difference for me was not only the product itself, but the supply discipline: shipments arrived as scheduled, and communication was always direct and solution-oriented. That consistency reflects a factory system I can trust across international projects."

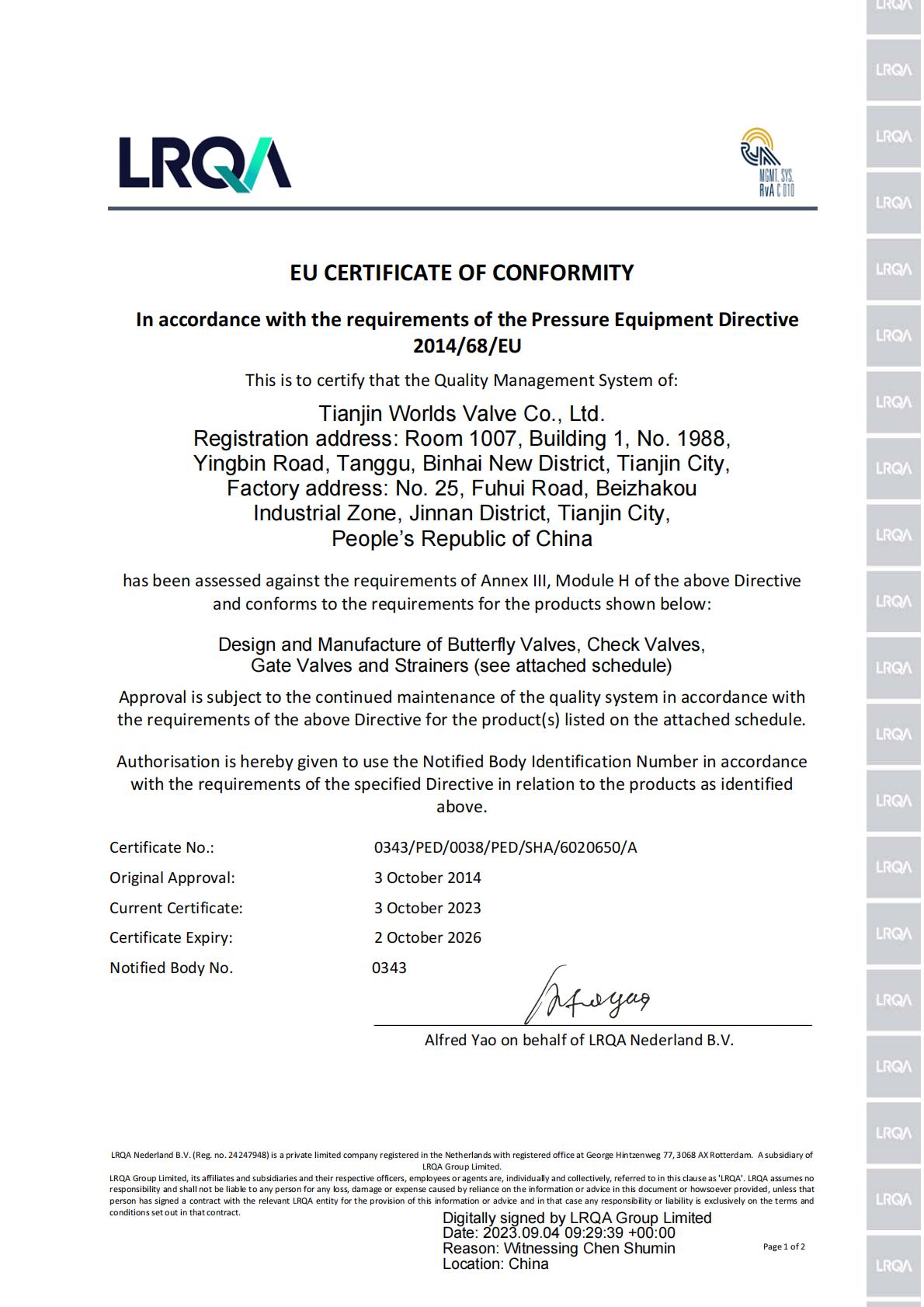

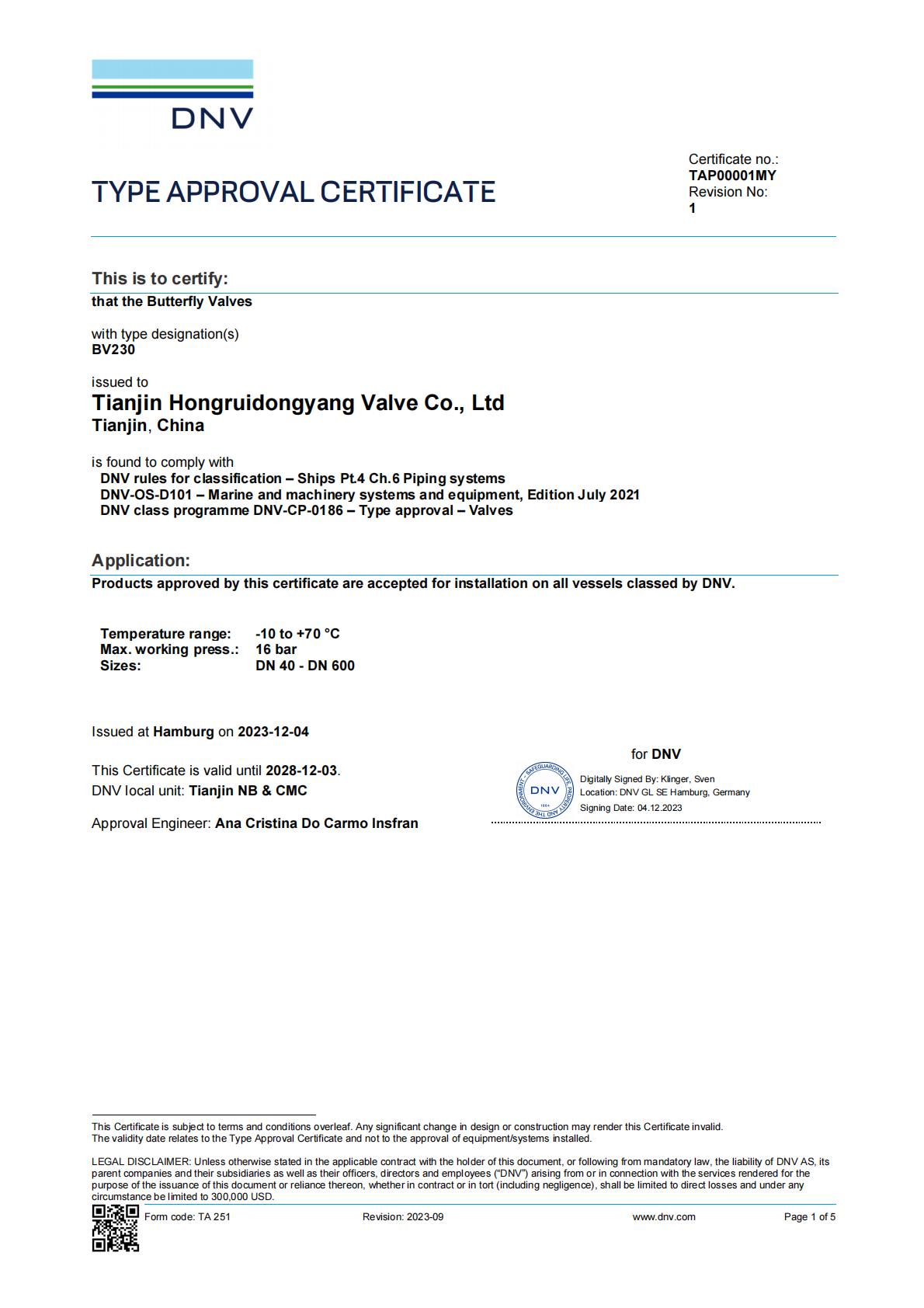

Our comprehensive certification portfolio ensures global market access and demonstrates unwavering commitment to quality, safety, and environmental standards.

Quality Management System — continuous improvement & customer satisfaction.

Pressure Equipment Directive compliance for safety and reliability.

UK Pressure Equipment (Safety) Regulations — UKCA conformity.

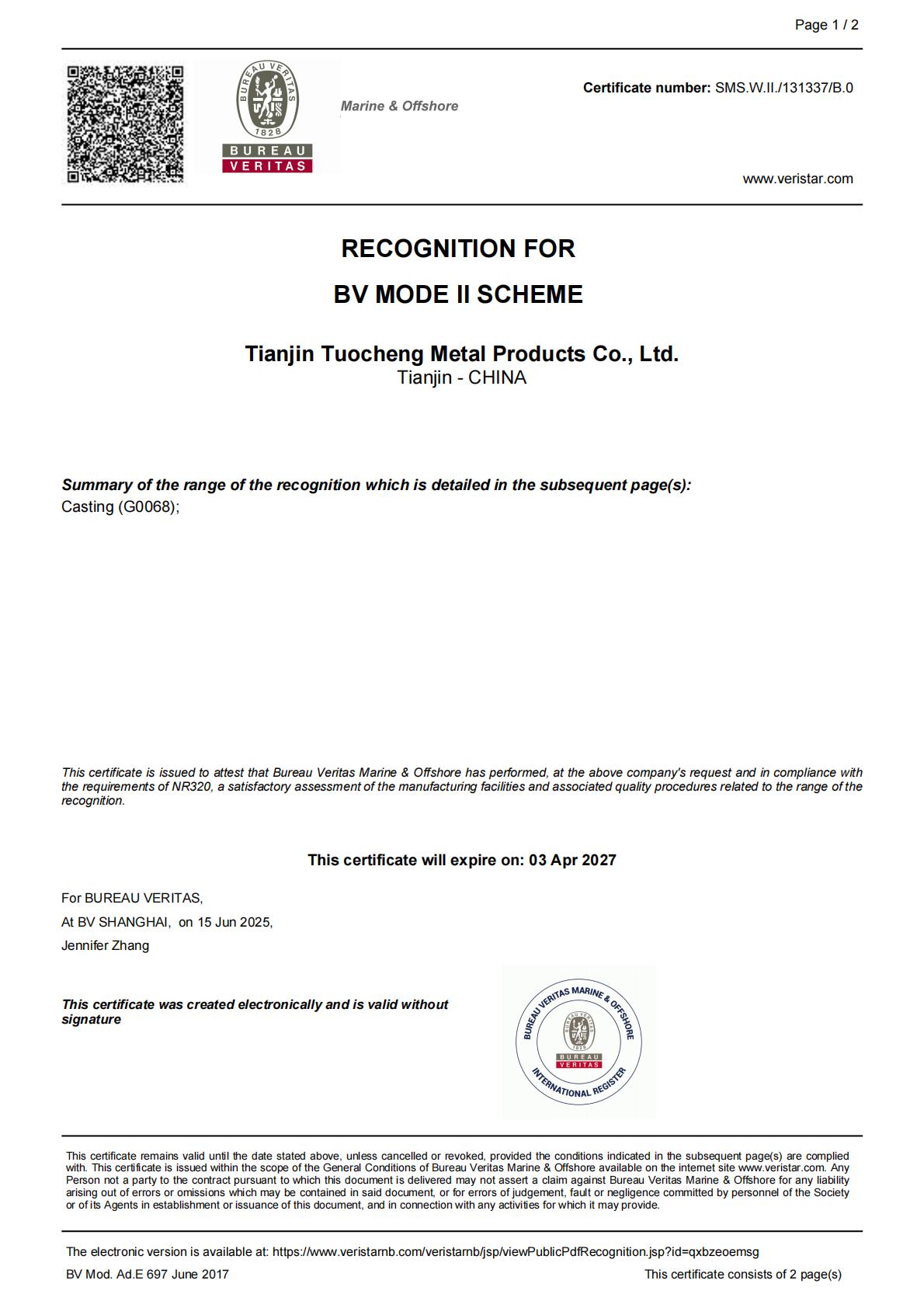

Marine & Offshore certification for performance and safety.

Potable water compliance for the UK market.

American Bureau of Shipping — Product Design Assessment.

Factory certification document for product conformity.

Marine & Offshore approval for check valve applications.

DIN, EN, BS, ANSI, JIS, GB/T

API 598, ISO 5208, EN 12266

ASTM, EN, JIS, GB standards

Direct answers for EPC contractors, system integrators, OEMs and industrial end users evaluating a China-based export manufacturer.

We focus on municipal water & wastewater, HVAC/building services, fire protection, shipbuilding/marine, and general industrial process water and utilities. As a manufacturer, we supply valves, strainers and piping components that integrate into EPC and system integrators' packages.

Core scope covers butterfly, gate, globe, check, ball, plug valves, foot/balancing valves and Y/Basket strainers. Typical ranges: DN25–DN1200, PN10–PN25, −10 °C to 200 °C; materials include ductile iron, carbon steel, stainless steel 304/316L and bronze. Designs follow DIN/EN/ISO with capability for ASME B16.34, API 609, DIN 3352 and EN 593; ANSI/DIN/JIS flanges available.

We operate under ISO 9001 with process checkpoints from incoming material to final assembly. Each unit is pressure tested at 1.5× working pressure, with QC records traceable by batch and operator. Third-party inspections (SGS/BV/TÜV) can be arranged on request; CE and DNV documentation is available where applicable.

Stocked/common specs can ship from ~5 working days; modified standard items typically 10–15 days; engineered-to-order usually 15–25 days. For urgent projects we can start production within ~72 hours and support phased deliveries or JIT under framework agreements.

We supply 2D drawings/3D models where needed, material certificates, pressure/leak test reports, operation & maintenance manuals and installation guides. All documents are available in English/Chinese and aligned with international project requirements.

We offer valve selection advice, flow resistance checks, materials compatibility evaluation and sealing scheme optimization, supported by CAD/CAE. Support is delivered remotely (video/phone/email) with 24-hour technical response. On-site installation or local maintenance is not included.

We support T/T and L/C; standard terms are 30% down payment and 70% before shipment, with credit terms for approved long-term partners. INCOTERMS®: FOB/CIF/DDP. Standard MOQ is 10 units (special items excluded). A 12-month quality warranty applies; issues are handled via remote diagnostics, repair or replacement per contract.

We export mainly to Europe, North America and Asia, including Germany, Italy, Spain, the United States, Japan, Singapore and Turkey. Factory verification options include on-site audits, third-party inspections, and provision of certificates/licenses and references.

Advanced manufacturing capabilities ensure consistent performance in critical industrial applications. Our technical expertise delivers reliable fluid control systems that meet the demanding requirements of modern industrial operations.

Connect with our technical experts and discover how we can optimize your fluid control systems for maximum efficiency and reliability.